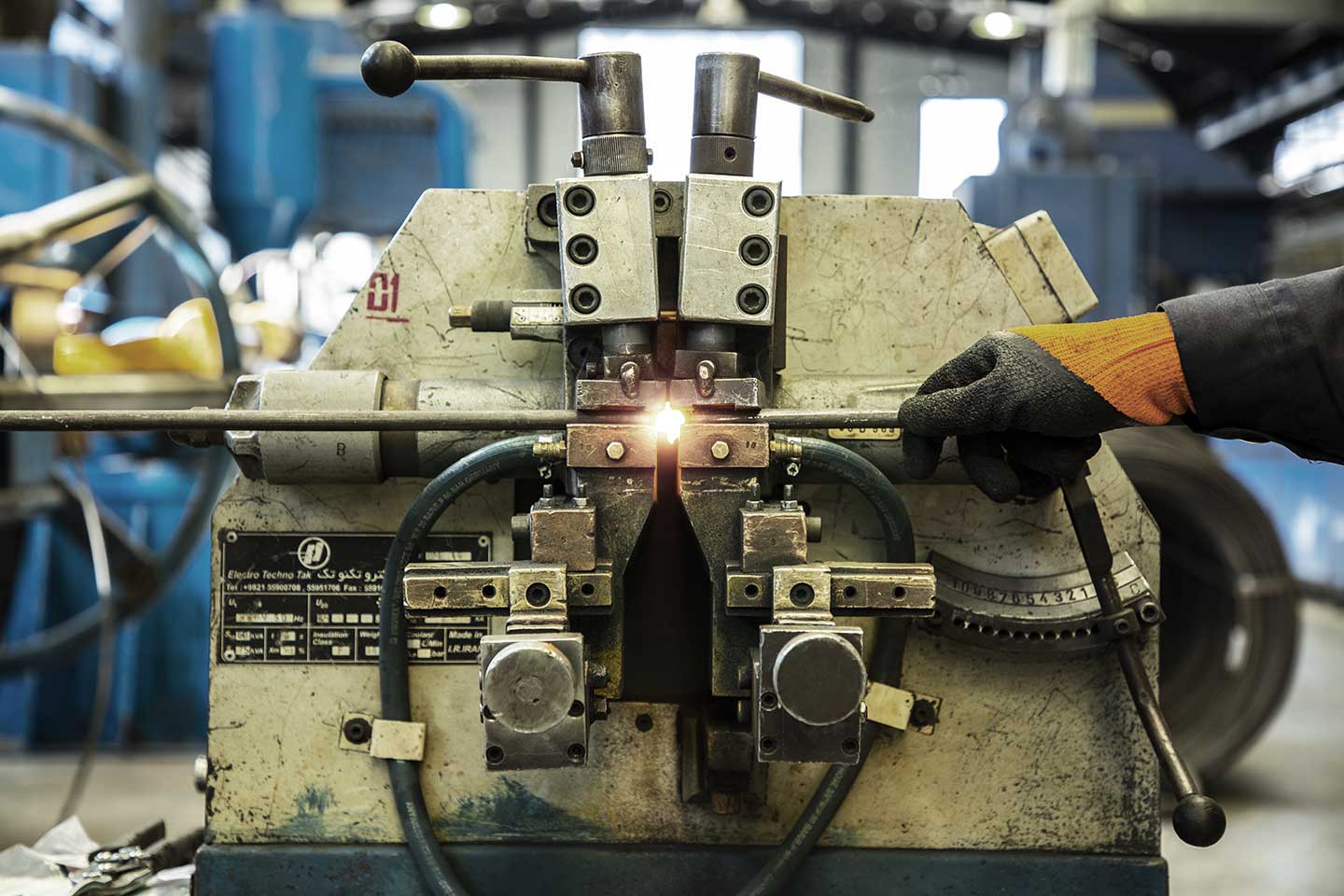

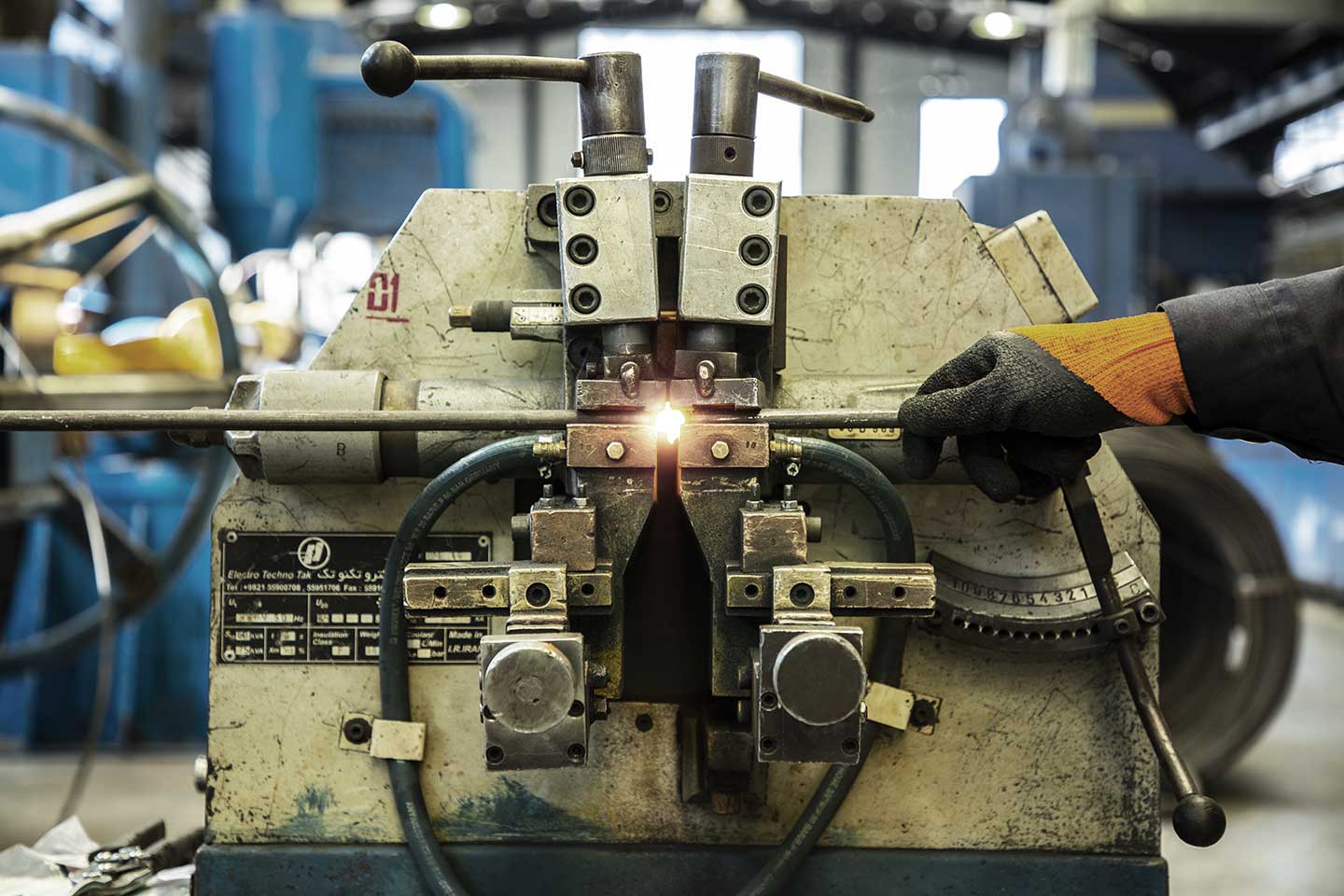

This product line is in fact a semiconductor frequency converter device that controls electronic equipment through switching by a rectifier controlled by silicon semiconductors (thyristor)

This method can convert high-frequency, three-phase electric energy to middle-frequency, single-phase electric energy which is generally used in the metal melting, surface quenching, etc. electrical tempering industries.

The most important benefits of this equipment:

- The efficiency of this equipment achieves higher than 90%

- The frequency of this equipment can easily change under load automatically

- Digital control increases the flexibility and accuracy of furnace control process

Product process / production technology

IHTW (Induction Heated Quenched and Tempering Spring Wire) is a spring wire with outstanding high tensile strength and high fatigue resistance used for suspension spring for automobiles produced by the cold forming process.

This is the 21st century product which enables cost reduction through light-weight spring wire, Ride comfort improvement through quality enhancement and design diversity.